Ranyal Textiles uses solar energy as a key contributor to its power mix, reducing reliance on conventional, fossil fuel-based electricity. Solar installations across our facilities generate renewable energy that directly supports production, helping to lower greenhouse gas emissions associated with textile manufacturing. This approach contributes to a smaller carbon footprint per unit produced and provides greater stability in energy costs over time. For our customers, it means working with a textile supplier that is investing in long-term, lower-impact infrastructure while maintaining manufacturing capacity and reliability.

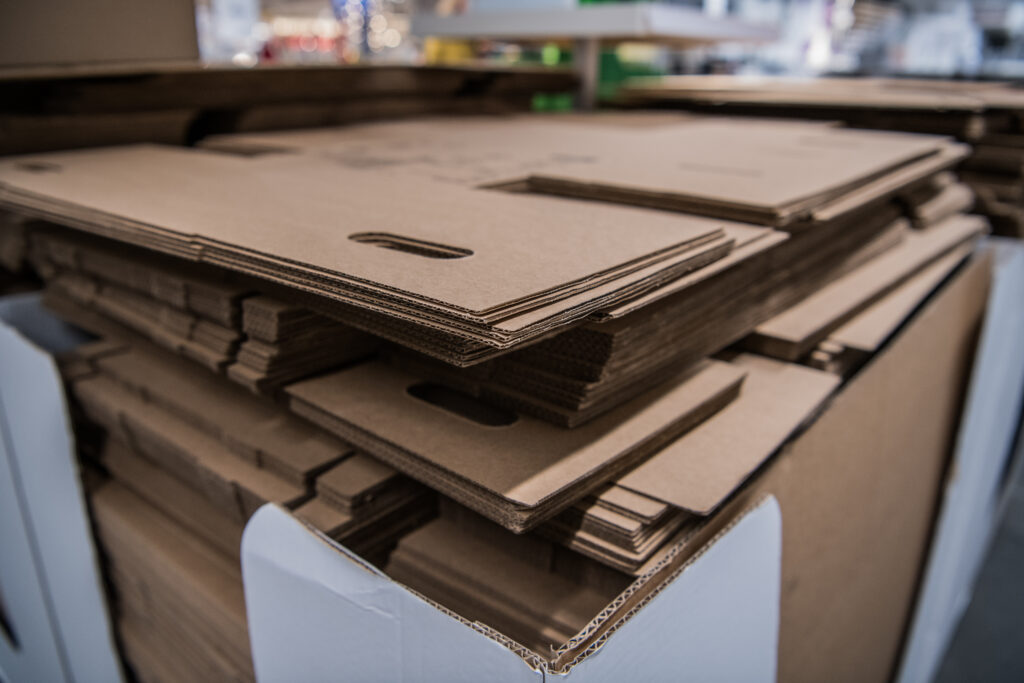

Ranyal Textiles extends its sustainability approach to packaging by prioritizing recyclable materials and systematically reducing plastic where practical. We evaluate cartons, inner packing and labelling to balance product protection, visual presentation and environmental impact. Where suitable, we move away from conventional plastic components and toward packaging formats that support recycling and lower landfill volumes. This approach allows customers to integrate Ranyal Textiles products into their own packaging and waste reduction strategies, contributing to more responsible supply chains from factory to end user.

Water is critical to textile processing, and Ranyal Textiles treats responsible water management as a core operational priority. We deploy advanced water recycling systems within our manufacturing processes to recover, treat and reuse water, reducing overall fresh water draw and lowering discharge volumes. These systems help protect local water resources, minimize pollution risk and support more stable processing conditions, which in turn underpin consistent product quality. For customers, this means partnering with a supplier that manages water usage in a disciplined, transparent manner while maintaining the technical standards required for hospitality and retail textile programs.

Ranyal Textiles uses recycled PET as a practical input for polyester yarn, using bottle waste as the starting point instead of relying only on virgin material. Clean, sorted bottles are processed into small flakes, then reformed into chips that can be melted and spun. The melt is pushed through fine holes to form continuous filaments, which are drawn to build strength and stability before being wound into yarn packages. The goal is simple: keep the yarn consistent for fabric production, while giving discarded plastic a second use in the textile line.By integrating rPET into the supply chain, we keep performance consistent while reducing dependence on virgin raw materials and giving plastic waste a second life in home textiles and apparel programs.